Blog

Predictive, Preventive and Corrective Maintenance

Predictive, Preventive and Corrective Maintenance

While there are many different types of maintenance strategies out there, most discussions about which strategy you should implement boil down to comparing the pros and cons of reactive maintenance versus preventive maintenance versus predictive maintenance.

Are you interested in joining this debate? The answer isn’t always so obvious.

But don’t worry, you’re not alone: over 87% of maintenance performed by US companies is entirely reactive. This isn’t good, because reactive maintenance causes 75% more failures and reduces equipment lifespan by up to 36%.

Budgets become unpredictable, and asset management becomes a nightmare.

Choosing the best strategy for a predictive and corrective maintenance plan

1- Requirements and costs of the predictive and corrective maintenance plan.

Get a clear picture of what each strategy offers, as well as the requirements and costs for each.

2- Define and review your needs

What types of assets you have.

What are the costs to replace an asset?

Cost of unscheduled and planned downtime.

3- Review available resources.

Training and training requirements for maintenance teams.

Time you can allocate to the implementation and training phases.

4- Choose the appropriate strategy

What you will need to implement. Consider implementing different maintenance strategies for different assets.

What is a Predictive Maintenance Plan?

Predictive maintenance is a proactive maintenance strategy that attempts to predict when a piece of equipment might fail so that maintenance work can be performed shortly before it happens.

These predictions are based on the equipment’s condition, which is assessed using data collected through the use of various sensors and condition monitoring techniques.

The goal is to save money and reduce costs so your company can focus on growth and not waste resources on predictable errors.

Like any other proactive maintenance strategy, predictive maintenance aims to:

• Minimize the number of unexpected breakdowns.

• Maximize asset uptime, which improves asset reliability.

• Reduce operating costs by optimizing the time you spend on maintenance work. In other words, perform maintenance only when necessary, virtually eliminating any chance of wasting time performing excessive maintenance.

• Improve your bottom line by reducing long-term maintenance costs and maximizing production hours.

Establishing a predictive maintenance plan in five steps

Step 1 – Identify Critical Assets

Start by identifying the key equipment and systems to include in the maintenance program. Assets with high repair/replacement costs, or that are critical to production, are often the best candidates for a Predictive Maintenance Program.

Step 2 – Create and Implement a Database

For a predictive maintenance program to be successful, another factor to consider is the availability of sufficient information that can provide insights into machine behavior.

Historical data for each piece of equipment can be available from various sources: printed spreadsheets, data from administrative or accounting software in other departments, maintenance records and charts, etc.

Step 3 – Analyze and Establish Failure Modes

Your company will need to perform an analysis on the critical assets identified above to determine their failure modes. In asset management, we have several methodologies based on standards and procedures. The methods can be based on several criteria: MTBF (Mean Time Between Failure), MTTR (Mean Time to Repair), Fault Tree, Event Tree, Reliability Block Diagram, etc.

Step 4 – Make Failure Predictions

With the most critical assets and failure modes identified, the next step is to design the appropriate modeling approach that will form the basis for failure predictions.

The end result of this phase is to deliver an automated system that will monitor operating conditions through installed sensors; understand and predict patterns created by data anomalies; and create alerts when deviations from established thresholds occur.

Step 5 – Implement the Maintenance Plan on Pilot Equipment

This is where predictive modeling is tested and validated by deploying the technology on a selected group of equipment.

If the process is executed correctly, there will be significant improvements in company operations, although noticeable impacts may take a few months to be seen. This will depend on the size and complexity of your organization.

Identify critical assets

Assets with high repair/replacement costs and critical to production are better candidates.

Create and deploy a database

Historical data for each asset may be available from multiple sources.

Analyze and establish failure modes

Choose the best methodology for each piece of equipment based on your asset management methodology.

Make failure predictions

Deliver an automated system with a fault monitoring model.

Implement the maintenance plan on the pilot equipment

Implement the maintenance plan on the pilot equipment

Validate by implementing the technology on a selected group of equipment.

What is a preventive maintenance plan?

A common question is how to differentiate between preventive and predictive maintenance.

The basic concept of preventive maintenance is to prevent problems with scheduled actions for maintenance teams, aiming to avoid downtime and increase equipment lifespan.

How are these actions scheduled?

Through procedures recommended by equipment manufacturers and based on internal history when the company has been operating with assets in this category for some time. This is scheduled maintenance, meaning it is performed according to a schedule and occurs regardless of actual damage caused by breakdowns or downtime.

Some examples of preventive maintenance are: periodic lubrication; systematic equipment inspections; part modifications or replacement; and instrument calibration and verification plans.

Common Questions When Developing a Preventive Maintenance Plan

- How much will I reduce the impact of failures according to my plan?

- Is it possible to detect and reduce functional failures in advance with the preventive actions I defined in my plan?

- Will my operations experience fewer potential and functional failures with a preventive maintenance plan?

Preventive maintenance can be divided into two categories.

- Systematic preventive maintenance: Performed periodically based on data and history.

- Conditional preventive maintenance: Performed when there is a decline in equipment efficiency.

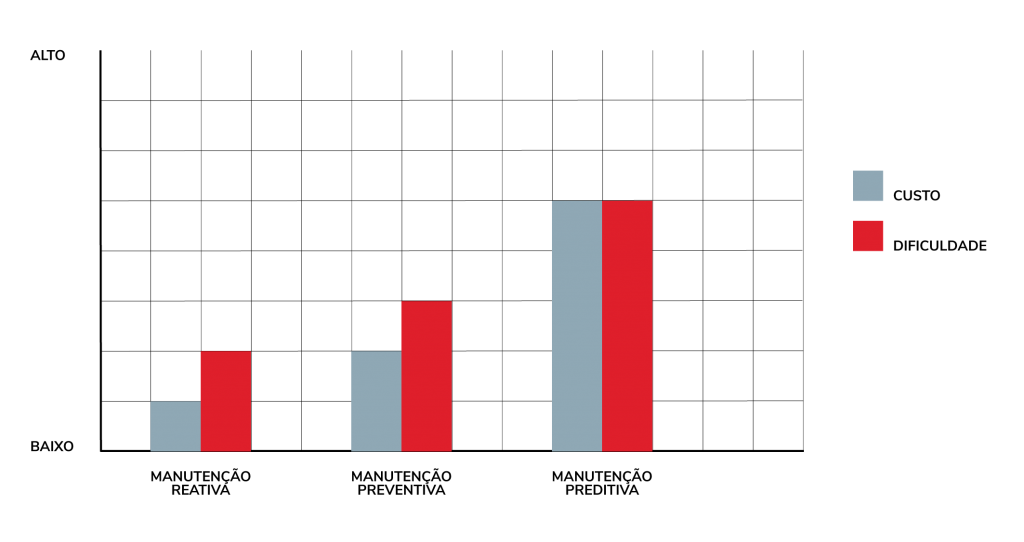

Comparison between the three main types of maintenance

Predictive maintenance is the best strategy in theory, but that doesn’t mean it’s the best option for all organizations or assets.

Each strategy has its advantages and disadvantages, so we decided to compare the three main strategies: predictive maintenance, preventive maintenance, and corrective maintenance.

We’ve divided it into three main sections:

1 – Pros and cons of each maintenance plan.

2 – Comparison charts (cost and difficulty of implementation, potential return on investment).

3 – How to choose the right strategy.

We hope this comparison provides a practical introduction to this topic and serves as a good starting point for deciding which types of maintenance you want to implement in your company.

Reactive maintenance

Reactive maintenance describes a maintenance strategy in which maintenance work is only performed after a failure occurs, or the asset becomes unavailable.

Pros

- Very simple to understand and use.

Requires minimal effort to implement and run. - Can be used without implementing sensors or software packages.

Cons

- High possibility of unscheduled downtime.

This often involves many hours of overtime. It can result in an unsafe work environment. Unexpected breakdowns reduce asset lifespan. - A lack of tracking provides little or no insight into your maintenance operations.

Preventive maintenance

PROS

- Minimizes unscheduled downtime and maximizes asset uptime.

- Provides a real-time overview of the current condition of your assets.

- Ensures minimal productivity interruptions, as some predictive maintenance activities can be performed on the asset while it is running.

- Optimizes the time you spend on maintenance work.

- Optimizes the use of spare parts.

- Improves asset reliability.

CONS

- Requires condition monitoring equipment and software to implement and run.

- You need a specialized skill set to understand and analyze condition monitoring data.

- High upfront costs.

May take a while to set up and implement depending on the size of your company.

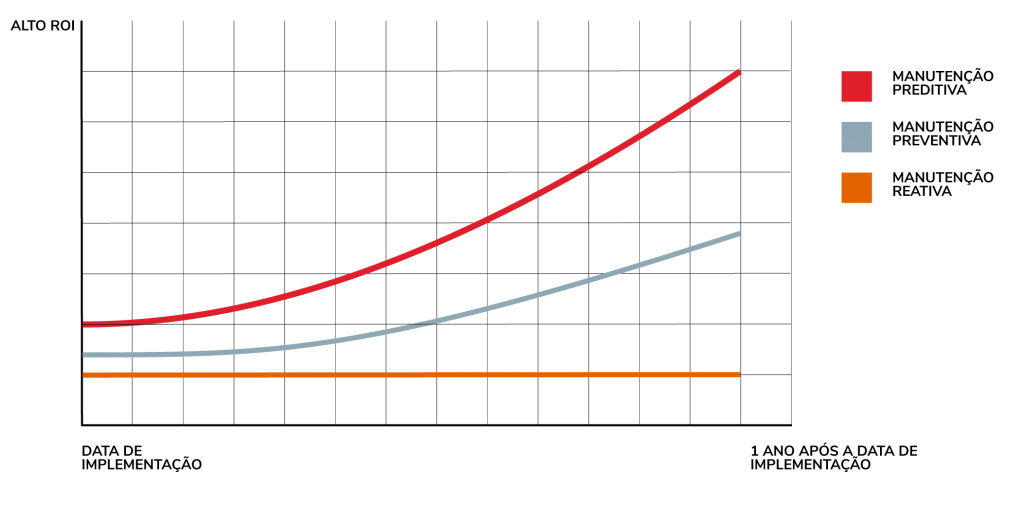

Comparison charts between maintenance types

Cost and Difficulty of Implementation

Reactive maintenance is inexpensive, but carries the risk of costly downtime.

Implementing predictive maintenance is often expensive because it involves purchasing sensor equipment and analytical software.

Return on Investment (ROI) Potential

Reactive maintenance can be costly in the long run.

Several studies estimate that preventive maintenance is 10% to 30% more cost-effective than reactive maintenance.

The same research shows that predictive maintenance is at least 10% more cost-effective than preventive maintenance.

Comparison charts between maintenance types

Detective Maintenance

This type of maintenance uses specialized equipment. The principle of detective maintenance is based on identifying occurrences that were not discovered during operation.

It is a methodology incorporated into control, command, and protection systems. Procedures are linked to a calendar with stipulated periods to correct hidden failures.

Total Productive Maintenance (TPM)

This type of maintenance is known as TPM because of its English name, Total Productive Maintenance.

The system was developed in Japan with the goal of eliminating losses, reducing downtime, lowering costs in companies with continuous processes, and ensuring quality.

TPM emphasizes proactive and preventive maintenance to maximize equipment operational efficiency. It is difficult to distinguish between the roles of production and maintenance teams; company management strongly encourages operators to train them to help maintain their equipment.

Maintenance efficiency is not the sole responsibility of a specific team. The culture of companies that practice Total Productive Maintenance is that everyone must contribute to ensuring that assets and equipment are always operating at their best.

Prescriptive maintenance is the evolution of predictive maintenance

In essence, prescriptive maintenance not only tells you when something needs to be fixed, but also suggests scenarios for how you might address the anticipated problem.

REACTIVE

Fix it when it breaks!

PREVENTIVE

Scheduled maintenance at regular intervals so the asset doesn’t break.

PREDICTIVE

Accurately predict when the asset will break, and perform maintenance accordingly.

PRESCRIPTIVE

Let the machines help decide how to avoid prediction failures.

The applicability of prescriptive maintenance is linked to advances in Artificial Intelligence and machine learning. It is also aligned with the principles of Industry 4.0, a term that emerged in 2012 in a document with suggestions for the German government, developed by a working group led by Siegfried Dais and Henning Kagermann.

According to the authors, six principles characterize the prescriptive maintenance project. They are as follows:

1- Real-time

2- Virtualization

3- Decentralization

4- Service orientation

5- Modularity

6- Interoperability

The trend is that we probably won’t wait long until prescriptive maintenance becomes the next big thing in the maintenance sector.

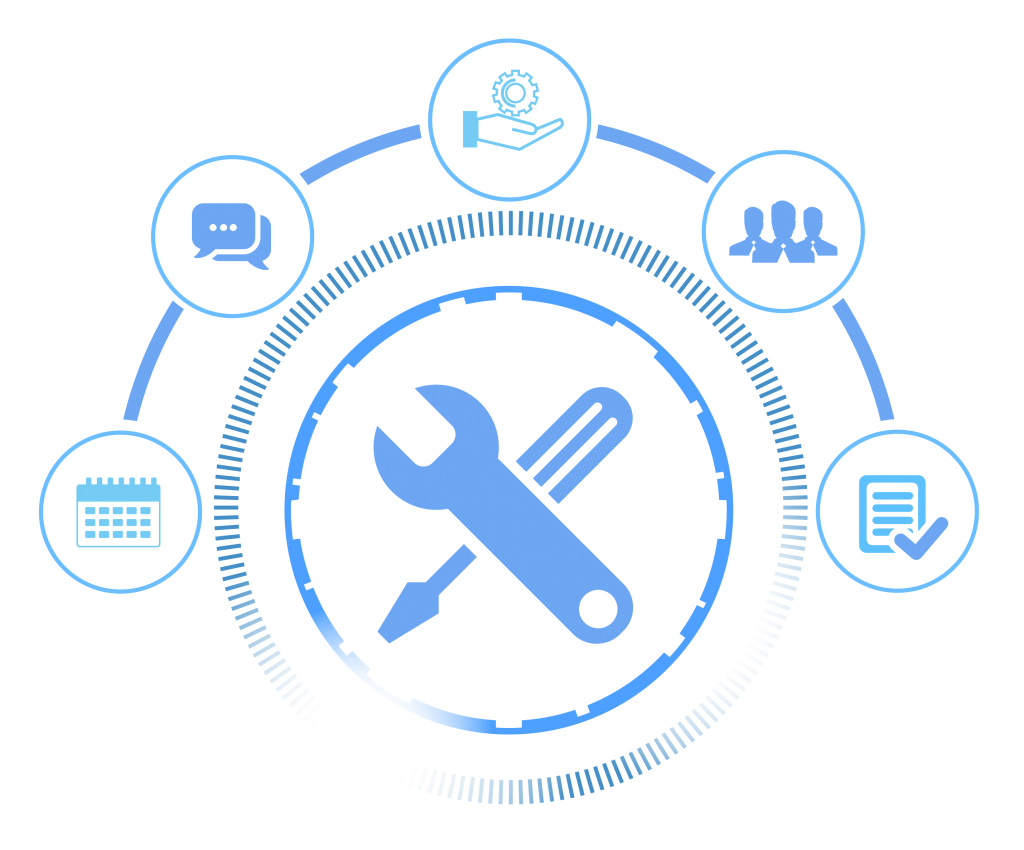

How IClass FS can help you with your maintenance strategy

Everything your maintenance plan needs

See the benefits your company can gain when using IClass FS.

Cost reduction through maintenance

Lower operating costs by properly carrying out preventive maintenance services. With maintenance activities recorded along with expected and completed costs, you spend less time on cost indicators and more on strategic improvements.

Standardized processes

Simple management via a computer or smartphone.

Spreadsheets no longer meet the demands of a 21st-century company. It’s like using an abacus to manage stock investments.

Open service requests for predictive maintenance

Everything is integrated in IClass FS.

An employee can open a service request for the maintenance team and transparently follow the entire process with quality. At the end of the process, evaluations can be submitted.

Preventive maintenance with recurring tasks

Include your recurring preventive maintenance tasks in the system.

Later, they can be distributed and scheduled by sector. Set up your plan and act quickly.

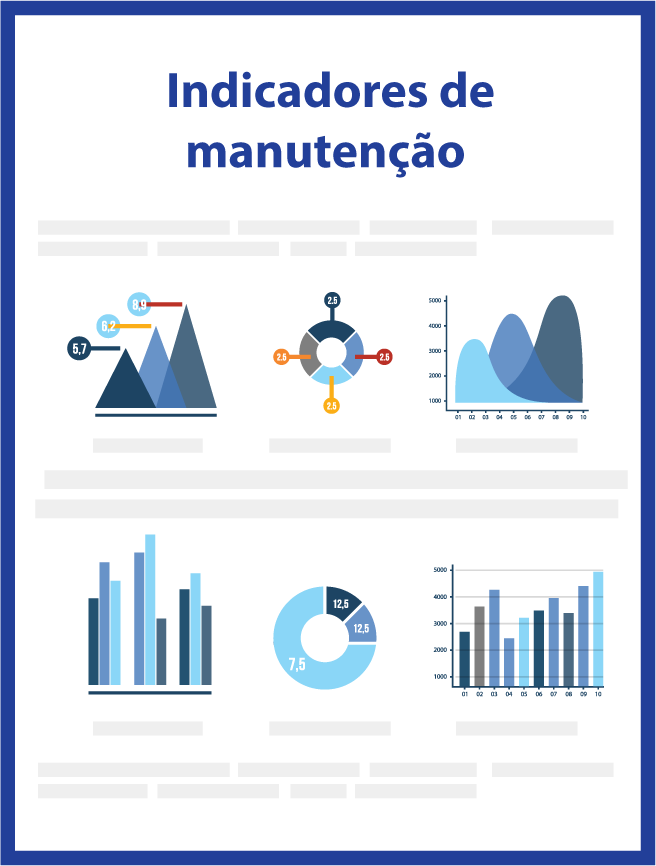

Monitoring key maintenance indicators

What would you like to monitor? Availability, Reliability,

MTBF (Mean Time Between Failures), MTTR (Mean Time To Repair), Service order backlog, Asset replacement value (ARV), Total equipment cost, and Total maintenance cost.

Schedule a demo and learn more.

Accelerate your company’s growth and gain competitiveness in your market.

Would you like to learn more about IClass One software?

Fill in the fields below and we’ll get back to you shortly.